STOCK's Newest Offering: ImmersaFlow™ Batch Retorts

ProMach is your partner from start to finish. Our product brands are grouped into distinct business lines that make the most sense to our customers, covering every function of the production line: Filling, Bottling & Capping, Decorative Labeling, Flexibles & Trays, Pharma, Handling & Sterilizing, Labeling & Coding, Robotics & End of Line, and Systems & Integration.

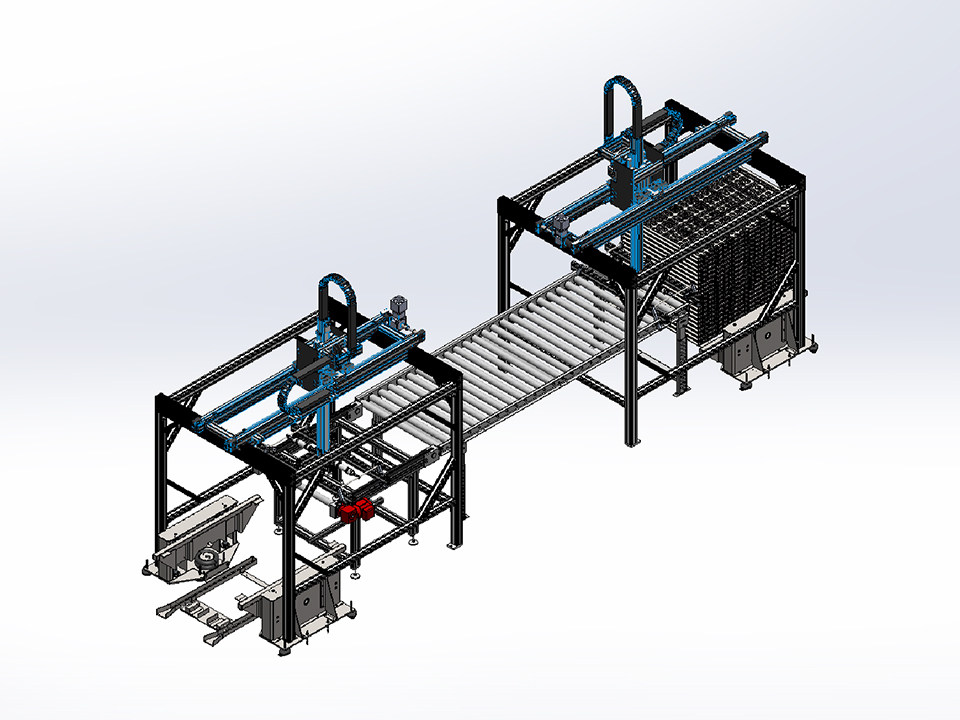

learn moreEntry-Level Product Handling

STOCK America is pleased to introduce our Entry Level Material Handling Systems. In the past Automation was an "All or Nothing Choice". Not anymore! We’ve developed a modular level of incremental steps which allow your facility to reduce labor and fatigue.

This application works with a standard build sterilizer. The automation of the door is not a necessity. The operator will be instructed when to open and close the door. Sensors added to the door will alert the micro-shuttle when a retort is ready to accept or release product. The intelligent ICON Process Software will direct the operator to move the load to a reject lane, if the retort logs a process error.

Entry-level product handling systems are diverse and include the:

- Micro-Shuttle

- Sweep Type Loader & Unloader

- Gantry Type Loader & Unloader

- Conveyor Network

- Basket Tracking Option

For more information about our capabilities and entry-level product handling machinery, please click on the relevant link on this page or contact us today to speak with a STOCK America representative.

This platform is executed in a two or four basket/cube configuration. The shuttle system is an X, Y application guided by rails bolted to the floor. The rails are fully adjustable and can be positioned to match the elevation of the retort and adapt to irregular floor elevations.

Provided are two modules, one for loading and the second for unloading.

The STOCK Gantry Style Pick and Place Loader/Unloader reduces the labor-intensive tasks of stacking and unstacking heavy trays to and from the retorts.

If the desire is to fully eliminate the use of manual trolleys, we can provide Interconnection Conveyors to transport baskets and accurately interface with the Retort Delivery System and Loader/Unloader.

To be absolutely sure each basket of product went through the retort cycle, basket tracking is available.