STOCK's Newest Offering: ImmersaFlow™ Batch Retorts

RELATED Handling & Sterilizing PRODUCT BRANDS

EXPLORE OTHER PROMACH BUSINESS LINES

EXPLORE OTHER PROMACH BUSINESS LINES

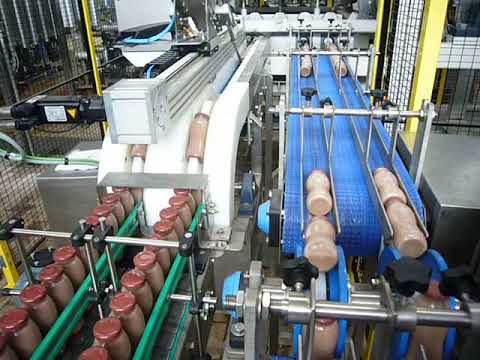

When customers need more than products simply moved from point A to point B, ProMach’s Handling solutions can accumulate, position, feed, orient, flip, stack, load, unload, distribute, rotate, reject, push, divert, index, and perform numerous other intricate product handling challenges. And when customers need to deliver shelf stable products to the marketplace, ProMach’s Sterilizing solutions span the entire range of retort technologies, from entry-level systems to entire automated retort rooms. ProMach backs these solutions with cellular line integration and engineering services to automate entire portions of production lines to achieve optimal performance.

ProMach is your partner from start to finish. Our product brands are grouped into distinct business lines that make the most sense to our customers, covering every function of the production line: Filling, Bottling & Capping, Decorative Labeling, Flexibles & Trays, Pharma, Handling & Sterilizing, Labeling & Coding, Robotics & End of Line, and Systems & Integration.

learn more- Continuous axial rotation (cylindrical containers) throughout the entire cycle allows for maximum process optimization

- Flexible retort packaging application for various container sizes on a single HYDROLOCK platform

- Can run up to four (4) different sized containers with similar geometry and process times

- Containers are fully contained within a carrier eliminating any possiblity of container or machine damage

- Available in saturated steam, steam/air, and steam-water-spray overpressure configurations

- Carrier assembly is fully removable from the pressure shell for safe inspection and cleaning

- FDA/USDA accepted ICON controls on a Allen/Bradley PLC platform

- 21 CFR Part 11 validation and documentation is standard

- Robotic or Servo loading and unloading systems fully integrated for cans, glass, pouch, bowl, cups and trays for any rigid, semi-rigid, and flexible container

- Idle mode for fast, energy-efficient restarts

- Fully energy balanced (cross-flow circulation and heat exchangers)

- Customizable with additional preheat and spray cool modules