STOCK's Newest Offering: ImmersaFlow™ Batch Retorts

ProMach is your partner from start to finish. Our product brands are grouped into distinct business lines that make the most sense to our customers, covering every function of the production line: Filling, Bottling & Capping, Decorative Labeling, Flexibles & Trays, Pharma, Handling & Sterilizing, Labeling & Coding, Robotics & End of Line, and Systems & Integration.

learn moreHigh Speed Automated Product Handling & Sterilization

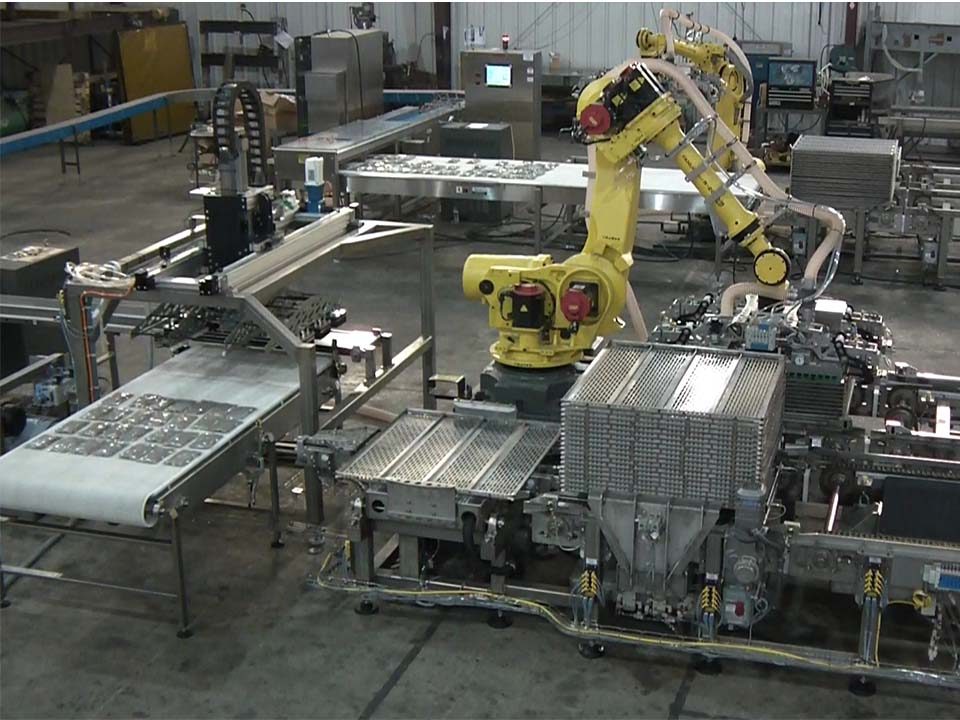

For completely automated lines STOCK continues to provide turnkey solutions for all types of containers in both batch and continuous applications. These systems require minimal operator intervention and produce high speed throughputs at a high rate of efficiency. Our full retort room solutions are available for all types of retorted containers integrated.

The STOCK retort room solutions are validated by our validated ICON control system including:

- Electronic process record keeping

- Basket tracking

- Food safety

Find out more about the completely automated high speed product handling equipment by contacting STOCK America today, via our contact tab or by calling our local office.

For Automated Retort Rooms, the retorts are designed to completely integrate with the material handling components.

Automated Product Delivery Systems provide operator free retort loading and unloading at high production rates by traversing across the floor in front of a bank of retorts to load and unload product.

The Automated Loaders and Unloaders incorporate all the features to provide the fastest sweep speeds for rigid containers in the market within a very robust stainless-steel frame controlled by an Allen Bradley PLC and Color Touchscreen.

The Automated Flexible Container Loaders and Unloaders stage products on an integrated infeed system for robotic or gantry style Vacuum Pick and Place operation.

The link between the Loader/Unloader and Retort Crate Delivery is the crate conveyor network.