Nutraceutical Beverages Industry

Retorts & Batch Sterilizers for Nutraceutical Beverages

Whether they are called “better-for-you beverages” or “health and wellness drinks”, liquid refreshments enhanced with nutraceutical ingredients are growing at a fast pace.

Nutraceutical Beverage Batch Retorts

STOCK can offer Batch Retorts capable of a wide variety of processing methods for Nutraceutical Beverages including Water Immersion, Steam Water Spray, Saturated Steam and Steam Air, as well as hybrid units that offer multiple methods for shelf stable beverage processing in a single unit. STOCK customizes equipment to provide the best product yield at the lowest cost per case. All STOCK sterilizers include our ICON SCADA Retort Controls, providing the highest level of food safety approved by FDA and USDA.

Nutraceutical Beverages can be considered non-specific biological therapies used to promote general well-being, control symptoms, and prevent malignant processes. The term “nutraceutical” combines the words “nutrient”, which is a nourishing food component, and pharmaceutical, which is a medical drug. The name was coined in 1989 by Stephen DeFelice, founder and chairman of the Foundation for Innovation in Medicine, which is an American Organization in Cranford, New Jersey.

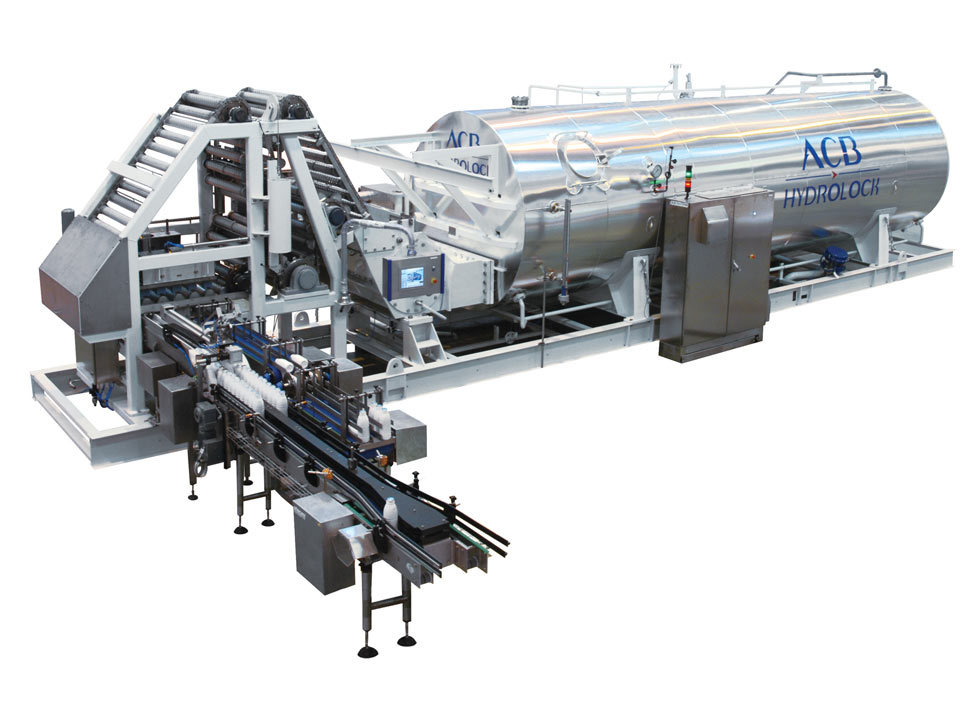

Continuous & Hydrolock Retort Systems

For Nutraceutical Beverage processors that do not require multiple container changeovers, STOCK’s Hydrolock Continuous Retort provides a perfect solution. This system receives product directly from the filler, automatically loading containers into the Continuous Retorts carriers that run through the system on a continuous drive chain, offering high volume throughput. After product exits the Continuous Retort it is automatically unloaded from the carriers and sent to end of line packaging. STOCK’s Continuous Retort saves energy, reduces manual labor requirements and yields a lower cost per case. All STOCK sterilizers include our ICON SCADA Retort Controls that meets or exceeds all regulatory requirements.

Manual & Semi-Automatic Material Handling Equipment

Upstream and downstream of the Retorts, STOCK offers multiple Material Handling solutions. From manual or semi-auto entry level automation, all the way through to high-speed loading, unloading and transport, STOCK has alternatives to accommodate your Nutraceutical Beverage processing needs.

We Will Help You Get Started

STOCK has a R&D / Laboratory Batch Retort and Continuous Retort installed at our facility in North Carolina. We can assist and guide you through the various stages required to develop commercial processes for the Nutraceutical Shelf Stable Beverage market.