STOCK's Newest Offering: ImmersaFlow™ Batch Retorts

ProMach is your partner from start to finish. Our product brands are grouped into distinct business lines that make the most sense to our customers, covering every function of the production line: Filling, Bottling & Capping, Decorative Labeling, Flexibles & Trays, Pharma, Handling & Sterilizing, Labeling & Coding, Robotics & End of Line, and Systems & Integration.

learn moreImmersaFlow Retort System - Features & Overview

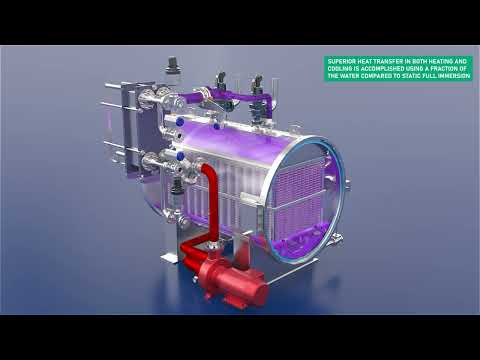

Watch our explanation and feature overview for the collaborative effort between Allpax and STOCK America, the ImmersaFlow™ static water immersion retort. ImmersaFlow™ utilizes a closed loop column of process water that is channeled through a plenum and closed wall product baskets. Outside of the basket, the retort shell is primarily empty, minimizing water usage and reducing the amount of heat energy required for the sterilization process. By confining and positively forcing the flow of the process medium through the load, ImmersaFlow™ can achieve 4 to 6 minute Come Up Times (CUT), with as little as a 2°F spread between the geometric center and perimeter of the load. Contact STOCK today to learn more.

Hi everyone, I'm Rick Elu, Vice President of Business Development for ProMach, and we're introducing our new ImmersaFlow product line. This is a revolutionary retort design focused on optimizing efficiency and reducing door-to-door time. Unlike other retort systems, the ImmersaFlow uses a closed chamber that forces processed media through the load, significantly decreasing overall come-up and cool times.

The operation is straightforward and super energy efficient. The main goal is to optimize the process and reduce the overall footprint required for multiple retorts. Typical system come-up times are impressively reduced, ranging from 8 minutes down to as low as 5 minutes in some tests. We've tested various container geometries, and the results have been consistent.

The cooling process utilizes the same methodology as heating by directing water through the process load. This approach allows us to cut cooling times down significantly. The channel flow design features an open area on each side, ensuring that we only heat the necessary amount of water. Unlike other retorts that simply throw water at the containers, ImmersaFlow provides perfectly linear cooling times.

We’ve observed cooling times reduced to as little as 10 minutes, compared to the typical 43 minutes required by conventional cooling methods. This innovative design offers optimized efficiency and a smaller operational footprint.